Introduction

Building automation professionals know that staying current with platform updates can make or break operational efficiency. The latest release of dglux 5 for Niagara 4.10 brings significant improvements that directly impact how facilities teams visualize, monitor, and control their building systems.

This comprehensive update addresses many of the pain points that have challenged users in previous versions. From streamlined user interfaces to enhanced security protocols, dglux 5 represents a substantial leap forward in building management technology.

Whether you’re managing a single facility or overseeing multiple properties, understanding these new capabilities will help you maximize your investment in Niagara-based building automation systems. Let’s explore what makes this release particularly noteworthy and how it can transform your daily operations.

Key Features and Enhancements

User Interface Improvements

The most immediately noticeable changes appear in dglux 5’s redesigned interface. Navigation has been simplified with intuitive menu structures that reduce the clicks needed to access critical functions. The dashboard layout now provides better visual hierarchy, making it easier to prioritize urgent alerts and routine monitoring tasks.

Color coding throughout the platform has been standardized to improve consistency across different system views. This seemingly small change significantly reduces the learning curve for new users and minimizes confusion during system handovers between team members.

The responsive design adapts seamlessly across desktop, tablet, and mobile devices. Field technicians can now access the same comprehensive data visualization tools whether they’re at their desk or troubleshooting equipment in mechanical rooms.

New Functionalities

Advanced analytics capabilities represent one of the most substantial additions to dglux 5. The platform now includes predictive maintenance algorithms that analyze equipment performance patterns to identify potential failures before they occur. This proactive approach can prevent costly downtime and extend equipment lifecycles.

Real-time data streaming has been enhanced to support higher-frequency updates without impacting system performance. Critical systems can now refresh data every few seconds rather than minutes, providing operators with truly current information for time-sensitive decisions.

Custom widget creation tools allow users to build specialized visualization components tailored to their specific operational needs. These widgets can combine multiple data sources into single, meaningful displays that communicate complex system states at a glance.

Performance Optimization

Behind-the-scenes improvements deliver measurable performance gains. Database query optimization reduces loading times by up to 40% compared to previous versions. This improvement becomes particularly noticeable when accessing historical trend data or generating comprehensive reports.

Memory management has been refined to handle larger datasets more efficiently. Buildings with extensive sensor networks and complex control sequences will experience more stable performance during peak usage periods.

Network bandwidth requirements have been reduced through improved data compression techniques. Remote sites with limited connectivity can now maintain reliable connections to central monitoring stations.

Benefits of Upgrading

Improved User Experience

The enhanced user interface translates directly into operational efficiency gains. Operators report spending less time navigating between screens and more time focusing on actual system optimization. Training periods for new staff members have decreased as the more intuitive interface requires less specialized knowledge to operate effectively.

Customizable dashboards enable each user to configure their workspace according to their specific responsibilities. Energy managers can prioritize consumption analytics, while maintenance teams can focus on equipment status and alert management.

Enhanced Security

Cybersecurity improvements address growing concerns about building automation system vulnerabilities. Enhanced encryption protocols protect data transmission between field devices and central servers. Multi-factor authentication adds an additional layer of protection against unauthorized access.

User permission management has been granulated to allow more precise control over who can access specific system functions. This capability helps organizations maintain security compliance while ensuring operational staff have appropriate access levels.

Regular security updates are now delivered through an automated update mechanism, reducing the administrative burden of maintaining current security protocols.

Better Integration

Expanded protocol support enables dglux 5 to communicate with a broader range of building systems and third-party applications. APIs have been enhanced to facilitate integration with energy management platforms, maintenance scheduling systems, and enterprise resource planning tools.

Cloud connectivity options provide flexible deployment scenarios. Organizations can choose between on-premises, cloud-hosted, or hybrid configurations based on their specific security and accessibility requirements.

Data export capabilities have been improved to support various formats required by different analysis tools and reporting systems. This flexibility eliminates data silos and enables more comprehensive building performance analysis.

Use Cases

Healthcare Facilities

Healthcare environments benefit significantly from dglux 5’s enhanced monitoring capabilities. Critical systems like medical gas delivery, clean room pressurization, and emergency power systems require continuous oversight with immediate alert capabilities.

The improved mobile interface allows facilities staff to respond quickly to critical alarms from anywhere in the facility. Predictive maintenance features help prevent equipment failures that could compromise patient safety or interrupt critical care operations.

Manufacturing Operations

Manufacturing facilities leverage dglux 5’s real-time data capabilities to optimize production environments. Temperature, humidity, and air quality control systems can be monitored and adjusted with precision to maintain product quality standards.

Energy consumption analytics help manufacturers identify opportunities to reduce operational costs without impacting production schedules. The integration capabilities allow building automation systems to coordinate with production management systems for optimal resource utilization.

How to Upgrade

Step-by-Step Upgrade Process

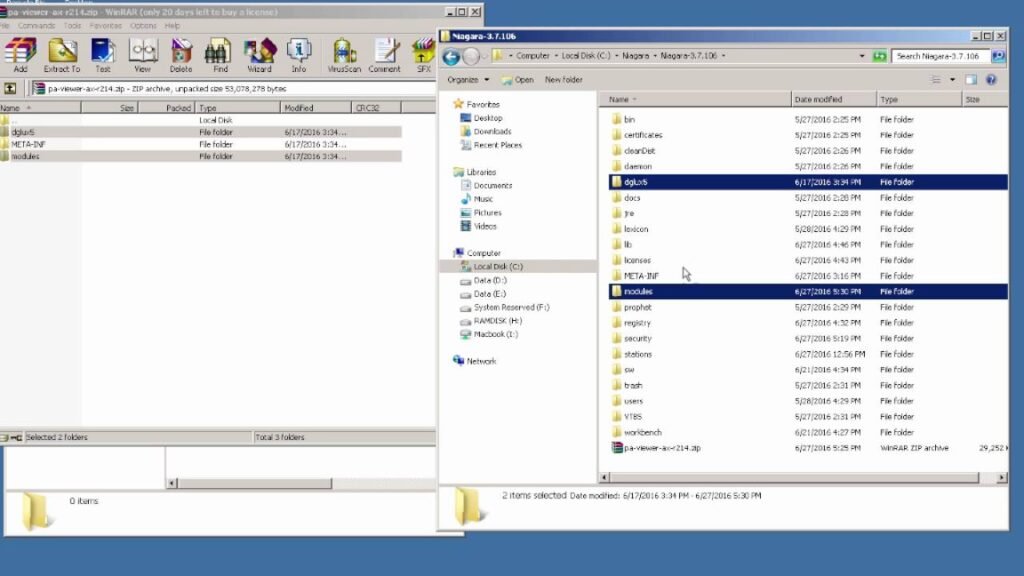

Before beginning the upgrade process, create a complete backup of your existing Niagara 4.10 configuration. This backup serves as a safety net if any issues arise during the transition.

Download the dglux 5 installation package from the official distribution channel. Verify the package integrity using the provided checksum before proceeding with installation.

Schedule the upgrade during a planned maintenance window to minimize operational disruption. Notify all system users about the planned downtime and expected restoration timeline.

Run the installation utility, which will automatically detect your existing Niagara configuration and migrate compatible settings to the new platform. The migration process typically takes 30-60 minutes depending on database size and system complexity.

After installation completion, verify that all critical system points are communicating properly and that historical data has been preserved correctly.

Considerations and Best Practices

Test the upgrade process in a development environment before applying it to production systems. This testing phase allows you to identify potential compatibility issues and develop solutions without impacting live operations.

Update user documentation and training materials to reflect interface changes and new functionality. Plan training sessions for key operators to ensure they can effectively utilize new features.

Review and update backup procedures to account for any changes in database structure or file locations. Verify that existing backup systems are compatible with the new platform version.

Consider upgrading during periods of minimal building occupancy to reduce the impact of any temporary service interruptions.

Frequently Asked Questions

Is dglux 5 backward compatible with older Niagara versions?

dglux 5 is specifically designed for Niagara 4.10 and newer versions. Organizations running older Niagara versions will need to upgrade their core platform before implementing dglux 5.

How long does the typical upgrade process take?

Most installations complete within 2-4 hours, including backup, installation, and verification procedures. Complex systems with extensive customizations may require additional time.

Will existing custom graphics and reports continue to work?

Most existing graphics will migrate automatically, though some may require minor adjustments to take advantage of new display capabilities. Custom reports should continue functioning without modification.

What training resources are available for the new features?

Comprehensive training materials, including video tutorials and documentation, are available through the support portal. Live training sessions can be scheduled for organizations upgrading multiple facilities.

Can the upgrade be rolled back if issues are encountered?

Yes, the upgrade process preserves the previous configuration, allowing for rollback if necessary. However, any data collected after the upgrade will be lost during rollback procedures.

Maximizing Your Building Automation Investment

dglux 5 for Niagara 4.10 represents a significant advancement in building automation visualization and control capabilities. The enhanced user interface, improved performance, and expanded functionality directly address the operational challenges faced by facilities professionals.

Organizations planning the upgrade should allocate adequate time for testing, training, and system validation. The investment in proper implementation will pay dividends through improved operational efficiency and reduced troubleshooting time.

Start planning your upgrade strategy now to take advantage of these improvements. Consider scheduling a consultation with your system integrator to develop a customized implementation plan that minimizes operational disruption while maximizing the benefits of this enhanced platform.