When it comes to cooling technology, one of the most common questions people ask is what does a heatsink do. At its core, a heatsink is designed to absorb and disperse heat away from sensitive electronic components, ensuring they operate efficiently and safely. From computer CPUs and GPUs to LED lighting and power electronics, heatsinks play a critical role in preventing overheating and maintaining performance.

In this guide, “Heat Pipes 101: What Does a Heatsink Do,” we’ll break down how heatsinks work, their connection to heat pipes, and why they’re essential in modern devices.

What Is a Heatsink?

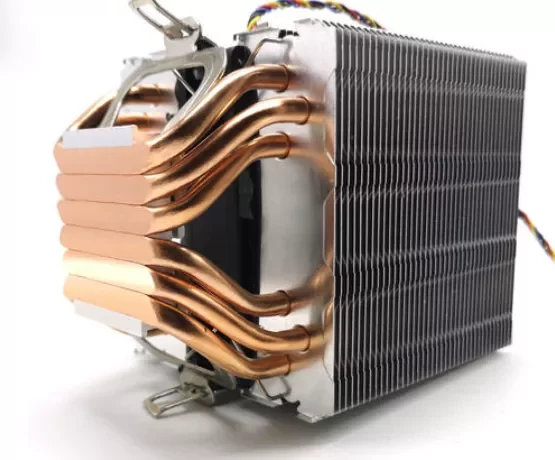

A heat sink is a key component in electronic devices that helps manage and remove excess heat. It passively cools a heat-generating component like a processor or chip by absorbing heat and dispersing it into the surrounding environment. Heat sinks prevent overheating, protect components, and ensure devices run reliably.

How Does a Heatsink Work?

A heatsink works by transferring heat away from electronic components to keep them cool. Here’s how it operates:

- Heat Absorption (Conduction): The heatsink’s base sits directly on the heat-generating component, like a CPU or GPU. Heat moves into the heatsink through conduction, aided by thermally conductive materials such as aluminum or copper.

- Heat Spreading: Once inside the heatsink, the heat spreads across fins or surface extensions, which increase the area in contact with the surrounding air or liquid. This larger surface area allows heat to dissipate more efficiently.

- Heat Dissipation (Convection & Radiation): The heat is released into the environment. Convection, through natural airflow or fans, carries heat away, while a small portion is also released via radiation.

A heatsink keeps electronic devices from overheating by absorbing, spreading, and releasing heat, helping them run smoothly and last longer.

Why Are Heatsinks Essential?

Heat sinks are essential in modern electronics because they keep components cool, ensuring devices perform well, last longer, and stay reliable.

- Prevent Overheating

Electronic parts like CPUs, GPUs, and LEDs generate heat during use. If not managed, this heat can cause malfunction or permanent damage. Heat sinks absorb and move this excess heat away, keeping components safe.

- Maintain Optimal Performance

Heat sinks keep electronic components cool, ensuring devices operate efficiently and consistently without slowing down from overheating.

- Extend Component Lifespan

High temperatures can wear out components faster. Heat sinks regulate heat, reducing wear and helping devices last longer.

- Enable Compact, High-Performance Designs

Heat sinks help manage heat in small, powerful devices, allowing compact designs without reducing performance. They are essential in electronics, automotive systems, and data centers.

Heat sinks play a key role in keeping modern electronic devices safe, efficient, and long-lasting.

Types of Heatsinks and Cooling Solutions

- Active Heat Sinks

Active heat sinks use powered components, such as fans or liquid pumps, to enhance heat dissipation. They are ideal for high-performance systems that require efficient cooling.

Advantages:

- Enhanced Cooling: Fans or pumps increase airflow or coolant circulation, improving heat transfer.

- Compact Design: Active components enable smaller heat sinks, making them ideal for space-limited applications.

Disadvantages:

- Noise: Fans can produce unwanted sound.

- Higher Power Use: External power is needed to operate fans or pumps.

- Maintenance: Moving parts can wear out and may require regular upkeep.

- Passive Heat Sinks

Passive heat sinks rely on natural convection and conduction to dissipate heat, without moving parts. They are best for applications where simplicity, reliability, and quiet operation are important.

Advantages:

- Silent Operation: No moving parts, making them ideal for noise-sensitive environments.

- Low Maintenance: Fewer components mean less upkeep and higher reliability.

- Energy Efficient: Do not consume extra power beyond the device’s operation.

Disadvantages:

- Limited Cooling: Less effective for high-heat components.

- Size Constraints: Larger surface areas improve cooling but can be a problem in small or compact designs.

- Hybrid Heat Sinks

These use both passive and active cooling to effectively handle different levels of heat.

Advantages:

- Adaptive Cooling: Operate passively under low heat and activate active cooling when needed.

- Balanced Performance: Efficient cooling while conserving energy when possible.

Disadvantages:

- Complex Design: Integration of both methods can make the system more intricate.

- Higher Cost: Additional components increase manufacturing and maintenance expenses.

Heat sink choice depends on cooling needs, space, noise, and upkeep. Selecting the right type ensures efficient thermal management and reliable device performance.

Applications of Heatsinks

Heat sinks are essential for keeping electronic parts cool, ensuring safe and reliable operation across many industries.

- Computers & Consumer Electronics

Used in CPUs, GPUs, RAM, and chipsets to prevent overheating and maintain stable performance. Compact designs are ideal for gaming consoles, routers, and smartphones.

- Industrial & Automotive Electronics

Help manage heat in power transistors, voltage regulators, and EV components like motors and chargers for efficient, long-lasting operation.

- LED Lighting & Power Electronics

Heat sinks help LEDs stay bright and last longer by keeping them cool. In power systems, they cool components like MOSFETs and IGBTs to prevent overheating and ensure safe operation.

- Data Centers & Telecommunications

Regulate heat in high-density servers and accelerators, preventing thermal throttling and ensuring efficient data processing.

Heat sinks keep electronics cool, improve performance, and extend their lifespan.

Choosing and Maintaining a Heatsink

Selecting the Right Heat Sink

- Thermal Requirements: Identify the component’s heat output, maximum operating temperature, and ambient temperature.

- Type:

- Passive: Relies on natural cooling, operates quietly, ideal for low-power devices.

- Active: Uses fans or pumps for high-power components like CPUs and GPUs.

- Hybrid: Combines passive and active cooling for flexible, efficient performance.

- Material & Design: Aluminum is light and affordable, while copper conducts heat better. Ensure fin design maximizes surface area and allows proper airflow.

- Airflow & Pressure: Consider whether the system uses natural or forced airflow and minimize airflow resistance to improve cooling efficiency.

Heat Sink Maintenance Best Practices

- Cleaning: Use compressed air every 3–6 months to blow away dust and dirt from the heat sink.

- Proper Installation: Ensure the heat sink makes full contact with the component and is correctly aligned.

- Thermal Interface Materials (TIM): Apply thermal paste or pads properly to fill gaps and enhance heat transfer.

- Monitor Temperatures: Use sensors or software to track component temperatures and prevent overheating.

- Ensure Airflow: Keep vents clear and maintain proper ventilation around the heat sink.

Choosing the right heat sink and taking proper care of it helps your electronic components stay cool, prevents damage from excessive heat, and keeps them functioning well for an extended period.

Conclusion: Heat Pipes 101 – The Role of Heatsinks

Heatsinks are crucial for keeping electronic devices cool, safe, and working reliably. They manage heat to keep devices cool, efficient, and durable. Heatsinks are used to keep things cool in devices like computers, electronics, industrial machines, cars, LED lights, power systems, and data centers.

Choose a cooling type based on heat, space, noise, and maintenance. Proper installation, regular cleaning, good contact with components, and monitoring temperatures are essential for effective cooling.

In short, heatsinks are key to designing electronics that run efficiently, stay compact, and last longer.